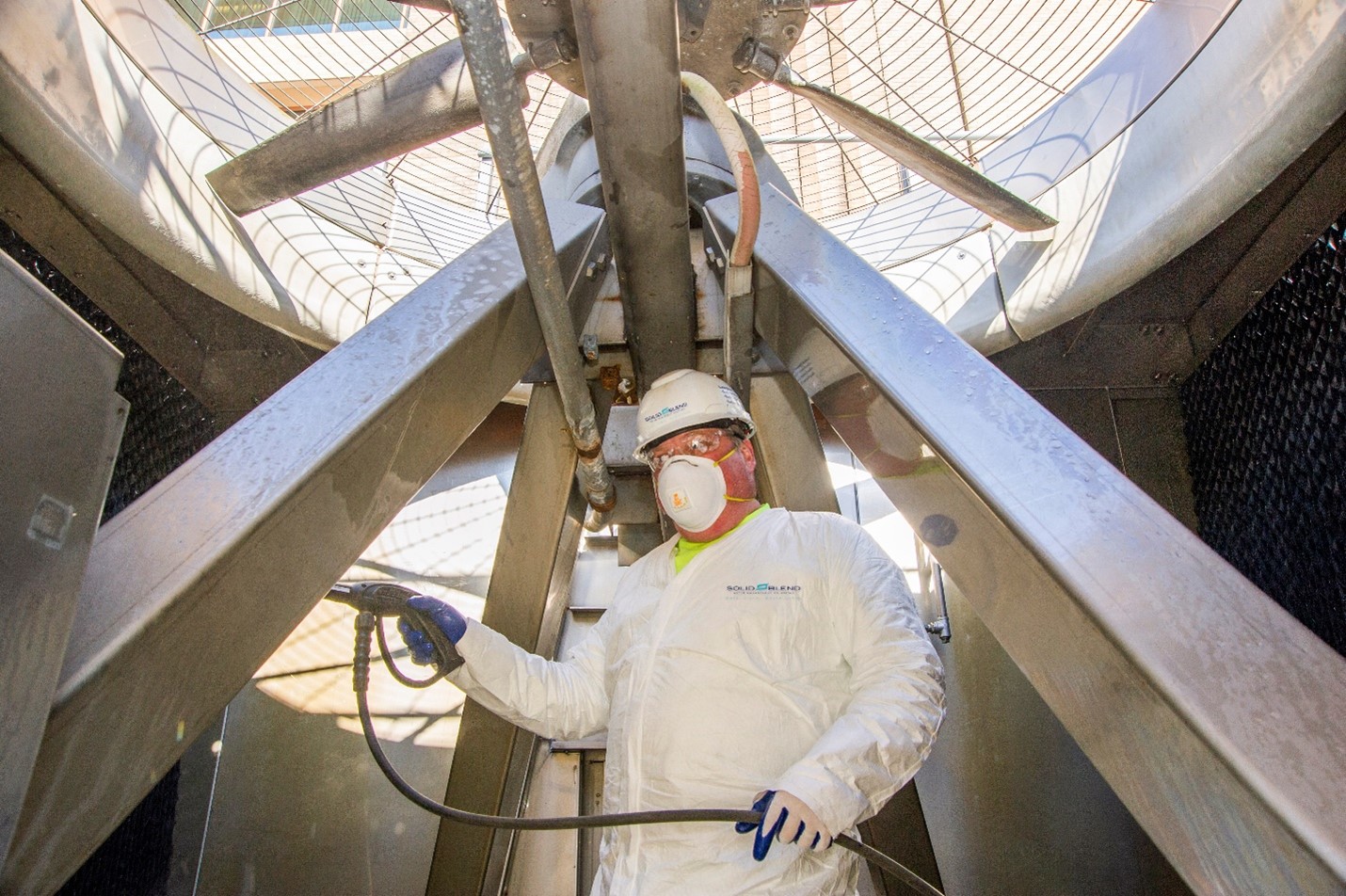

As we went out in the cold to scrape the ice off our cars (again), we found ourselves looking forward to warmer temperatures ahead. We, like you, also started to think about how we should probably clean out our cars, our closets, our garages, and well, all of the things. As you start your spring cleaning checklist, make sure to include your cooling tower. Yep – you read that right! According to ASHRAE guidelines, your cooling tower should be cleaned and disinfected prior to restarting it.

ASHRAE guidelines are different for restarting from a dry versus wet layup.

Dry Layup Process

When working with a dry layup, be sure to thoroughly clean the outside of the tower prior to restarting. As you fill the system with water and restart the condenser water pumps, leave the cooling tower fans off. Disinfect your system with a biocide or sodium hypochlorite. Once residual levels are maintained for a period of six hours, turn the fans on and return your cooling tower to service.

Wet Layup Process

When working with a wet layup, the process should look slightly different. Begin with cleaning and removing solid debris from sump and storage tanks. Again, ensure your fans remain off during this process. Pretreat the stagnant water with a biocide or sodium hypochlorite. After pretreatment levels are maintained for six hours, turn on the pumps to allow your cooling towers to fill – still keeping the fans off. After another six hours of consistent residual levels, then turn on the fans, returning your tower to service.

3 Important Tips

1. Leave your cooling tower fans off during water refill, disinfection, and pretreatment process until residual levels are maintained. Doing so reduces the risk of releasing any bacteria into the air during the process.

2. Both startup processes follow the same residual guidelines. For a sodium hypochlorite treatment, you want to establish a residual of 4 to 5 mg/L (ppm) at a pH of 7.0 to 7.6 to safely restart your system. For a biocide treatment, follow manufacturer’s recommendations on residual level.

3. Once your system is restarted, follow your Water Management Plan (WMP) to maintain safe operation. For a full rundown on your seasonal process check out our procedure guide.

Still have questions about restarting your cooling tower? Need help adjusting your WMP to keep up with frequent changes in requirements? Contact us, today.